'Ripe for Disruption' 5 New Construction Technologies Changing the Way We Build

According to Mckinsey, the construction sector has the lowest productivity gains of any industry. Will these new construction technologies change all that?

For a sector with a global turnover of $10 trillion, productivity concerns are a harbinger of doom, and it doesn't help that we are overwhelmed with information about the likelihood for disruption in the industry – new construction technologies that will fundamentally change the way the market evolves.

A recent report by the consulting firm on construction’s digital future indicated R&D spending in construction was, to its detriment, well behind that of other industries. McKinsey predicts that the industry is overdue in embracing newer technologies: “ripe for disruption”.

So, what are the next wave of construction technologies that are likely to enhance efficiency, mitigate risk and disrupt the construction industry?

1. Robot Automation

Disappointing news for the sci-fi buffs among us, but “robot labour” technologies have not progressed as quickly as expected – automation systems need very structured environments. In any case, robotics is giving rise to construction technologies that will change how, and where, buildings are made.

Australian company, Fastbrick Robotics pioneered a robotic construction technology that vastly improves the speed, accuracy, cost and waste management of the brick construction industry. The Hadrian X claims to be able to complete the brickwork on a home within 1-3 days, laying 1000+ standard bricks per hour.

Bricklaying robotics are already being put to use. Construction Robotics’ invent, SAM100, was sold to Wilhelm Construction last year. SAM is able to lay around 2000 bricks per day, a 400 per cent increase in productivity.

Studies show that the automation of jobs in this area will be up to 75 per cent, though before we all panic, the prediction is not that the jobs will simply be slashed but altered. As FastBrick helpfully points out, the technology is only an evolution, enabling the bricklayers of today to “transition from laborious and unsafe practices to being machine operators and site quality supervisors providing a physically sustainable career path”.

2. New Building Materials

Building materials often account for more than half the cost of projects, and conventional materials like concrete make up most of the demand – not to mention the environmental cost. The last decade has brought about perhaps the greatest innovation in construction technologies we have seen in building materials throughout the last century. Here are a few innovative materials we may be seeing more of: Self-healing concrete

Developed by microbiologist Henk Jonkers and concrete specialist Eric Schlangen, the concrete mix uses bacteria as a healing agent to close concrete cracks; it is embedded with tiny capsules of sodium silicate and when a crack forms the capsules rupture, releasing a gel-like healing agent that hardens to fill the void. Though other researchers have invented similar concrete bacterial combinations, embedding glass capillaries or polymer microcapsules to achieve similar results, Jonkers and Schlangen expect their mix to be the most cost-effective.

Digestive “smart” bricks

The smart bricks are being developed as part of the Living Architecture (LIAR) project coordinated by Newcastle University. The “digestive” bricks will be able to extract resources from sunlight, waste water and air.

Professor Rachel Armstrong explains: “The best way to describe what we’re trying to create is a 'biomechanical cow's’ stomach. It contains different chambers, each processing organic waste for a different, but overall has related purpose – like a digestive system for your home or your office.” The bricks will make up a bio-reactive façade that can be easily incorporated in housing, public buildings and office spaces.

Carbon nanotubes

Nanomaterials are ultra-lightweight materials that, though currently in the research stage, have the strength to function as a substitute for steel reinforcement in structures and foundations.

Aerogel insulation

One of the least dense substances on Earth and another construction technology disrupting the industry is Aerogel. Aerogel is a foam-like solid material that holds its shape despite being 99.98 per cent air. Aerogel has super-insulating properties, two to four times the insulating power of traditional fibreglass or foam insulation. Though still relatively expensive, Aerogel insulation has been used in a number of installations in buildings internationally.

3. 3D Printing

Can 3D printing help bring the laborious, complicated and intricate designs resigned to previous centuries, back in fashion? Architectural engineer Dr Phillippe Block seems to think so.

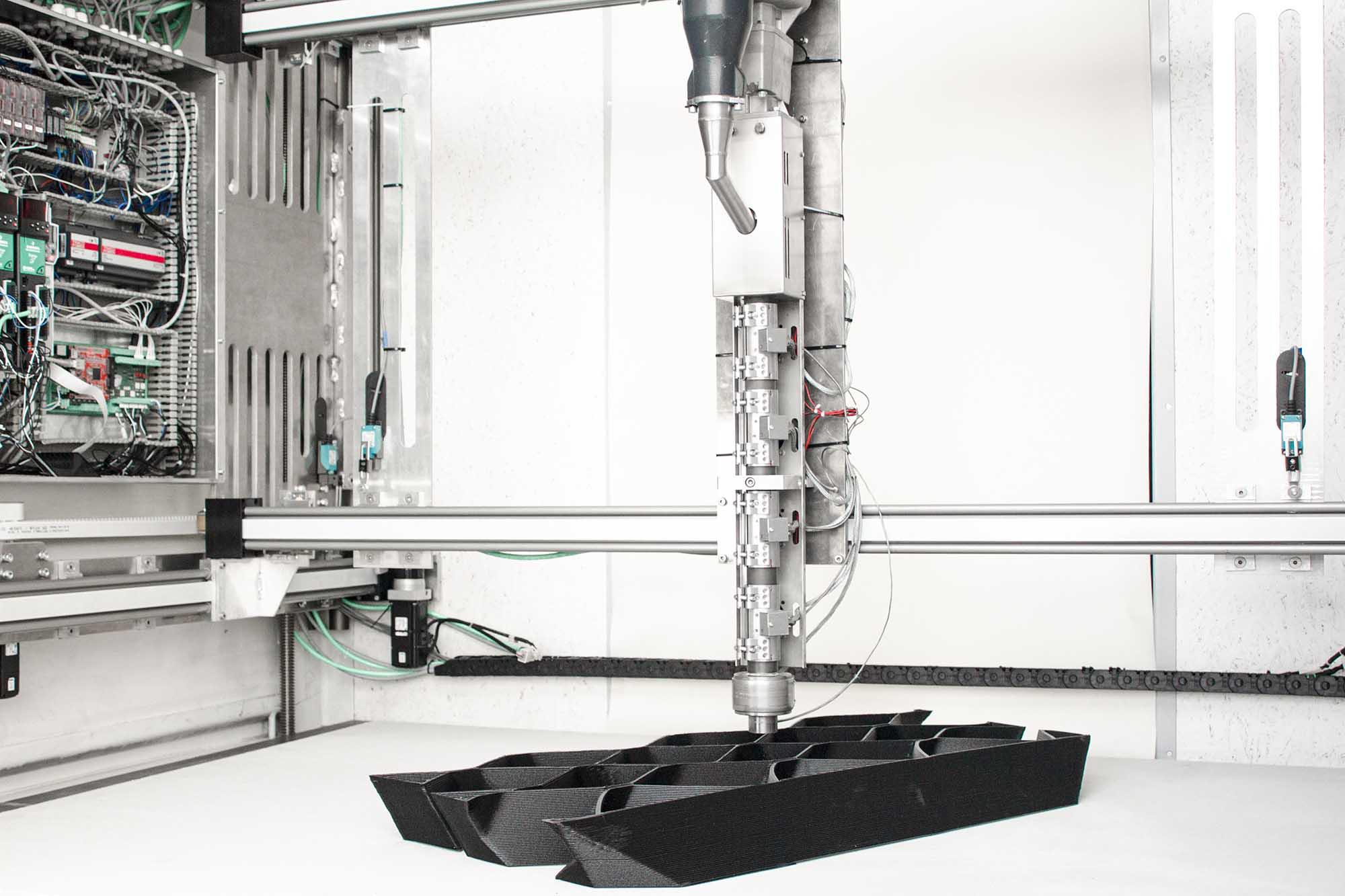

In a recent project, NEST, Dr Block’s group will make the floors for a part of the building called “HiLo”. He will be collaborating with Australian architect, James Gardiner on the project. James Gardiner developed FreeFab, the first 3D-printing construction technology to be used in a big commercial building project.

Describing the construction technology as “transformative” the FreeFab wax system prints moulds – rather than attempting to print structural material directly which, though being done on a small scale, is still fraught with problems. FreeFab’s moulds can be melted down and poured back into the tank – re-extruded into a new form. Traditional moulds, composed of wood and polystyrene, can only be used to produce a single shape and then they are discarded, sent to landfill.

Outside of FreeFab’s wax moulds, 3D-printing in construction is looking promising: there are 3D printed concrete houses in China, a fully functioning office in Dubai and, in Australia, the RMIT Architectural Robotics Lab is doing interesting work in applying robotics to architectural design, building fabrication and construction.

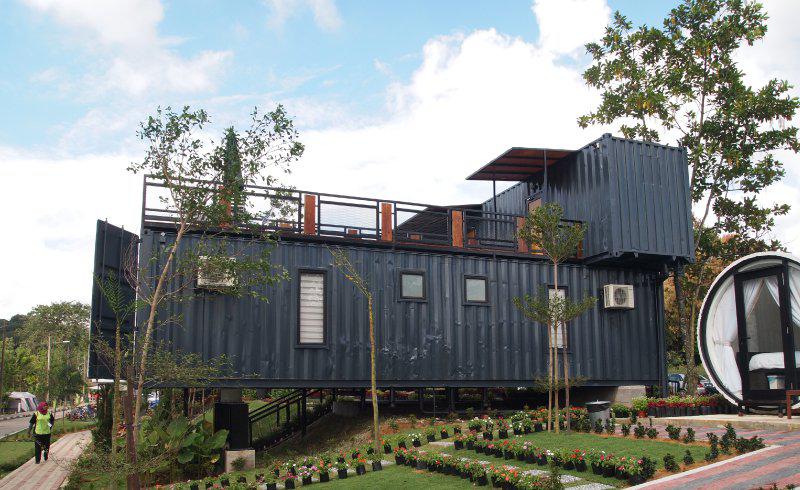

4. Prefabricated & Modular Homes

Off-site construction technologies are not new – the manufacturing of the components of a structure in a factory and transporting complete or semi-compete assemblies to the construction site has been done for decades. It is estimated that 85 per cent of the industry use prefabricated processes on projects even though 80 per cent of all construction work is still done on-site.

The benefits of shifting on-site construction works to off-site prefabrication are straightforward: reducing reliance on labour and providing safer workplaces, minimising the impact on the surrounding neighbourhood and reducing environmental waste during construction.

The growing demand for environmentally sensitive construction means traditional practices must adapt. A traditionally derided building model, factproduced homes have been experiencing a sort-of resurgence. KB Home, a homebuilding company based in the US, last year unveiled a new construction technology model - “smart” home built entirely in a manufacturing plant.

Dan Bridleman, senior vice president for sustainability, technology and strategic sourcing at KB Home explains, “automobiles, airplanes and others have been able to utilise these same techniques. Ultimately, this is about cost, it's about efficiency and it's about speed.”

5. Augmented Reality

Digi-Capital, a Californian firm of merger and acquisitions advisors, expects that of the $108 billion a year which it predicts will be spent by 2021 on augmented reality and virtual reality combined, augmented reality will take three-quarters. So, yes, there is a difference between the two: augmented reality supplements the real world by laying computer-generated data over it where virtual reality aims to “drop” users into an artificial real world.

Gilbane Building Company, a construction firm based in Rhode Island, is one of the early adopters of this construction technology. Usually working off paper blueprints or digital models viewed on an iPad, Gilbane senior manager John Myers, has been testing Microsoft’s AR headset, Hololens, a self-contained, holographic computer which allows Myers to get a closer look. In doing so, he has spotted construction issues ahead of time that have save Gilbane around $5000 in labour costs. The technology has been adopted by the engineering firm AECOM, architecture firm Gensler and the China State Construction Engineering Corporation.